NFCStack: Identifiable Physical Building Blocks that Support Concurrent Construction and Frictionless Interaction

UIST '22

Chi-Jung Lee, Rong-Hao Liang, Ling-Chien Yang, Chi-Huan Chiang, Te-Yen Wu, Bing-Yu Chen

We present NFCStack, a physical building blocks system that supportsboth stacking and interaction based on near-field communication (NFC). The system consists of a portable station that can support and resolve the order of three types of passive identifiable stackables: brick, block, and adapter. The bricks support stable and sturdy physical construction, whereas the blocks support effortless tangible interactions. The adapter provides an interface between the two types of stackables and turns the top of a stack into terminals for detecting the interaction events of NFC-tagged objects. Compared with the previous systems based on NFC or radio-frequency identification (RFID) technologies, the NFCStack system is portable, supports simultaneous interactions, and resolves the stacking and interaction events responsively even when the objects are not strictly aligned. A series of evaluation results show the system effectively supports a full-stack, 12 layers of rich-ID stacking with the three types of blocks, even if every block is stacked on each other with a 6mm offset. Based on the evaluation results, we also illuminate possible generalizations such as extending this system from stacking to 2.5D construction. With our proof-of-conceptimplementation, we demonstrate the interaction styles through several educational application examples and discuss the design implications for future research.

[Paper] [Video] [Digital Library]

Want to make your own NFCStack?

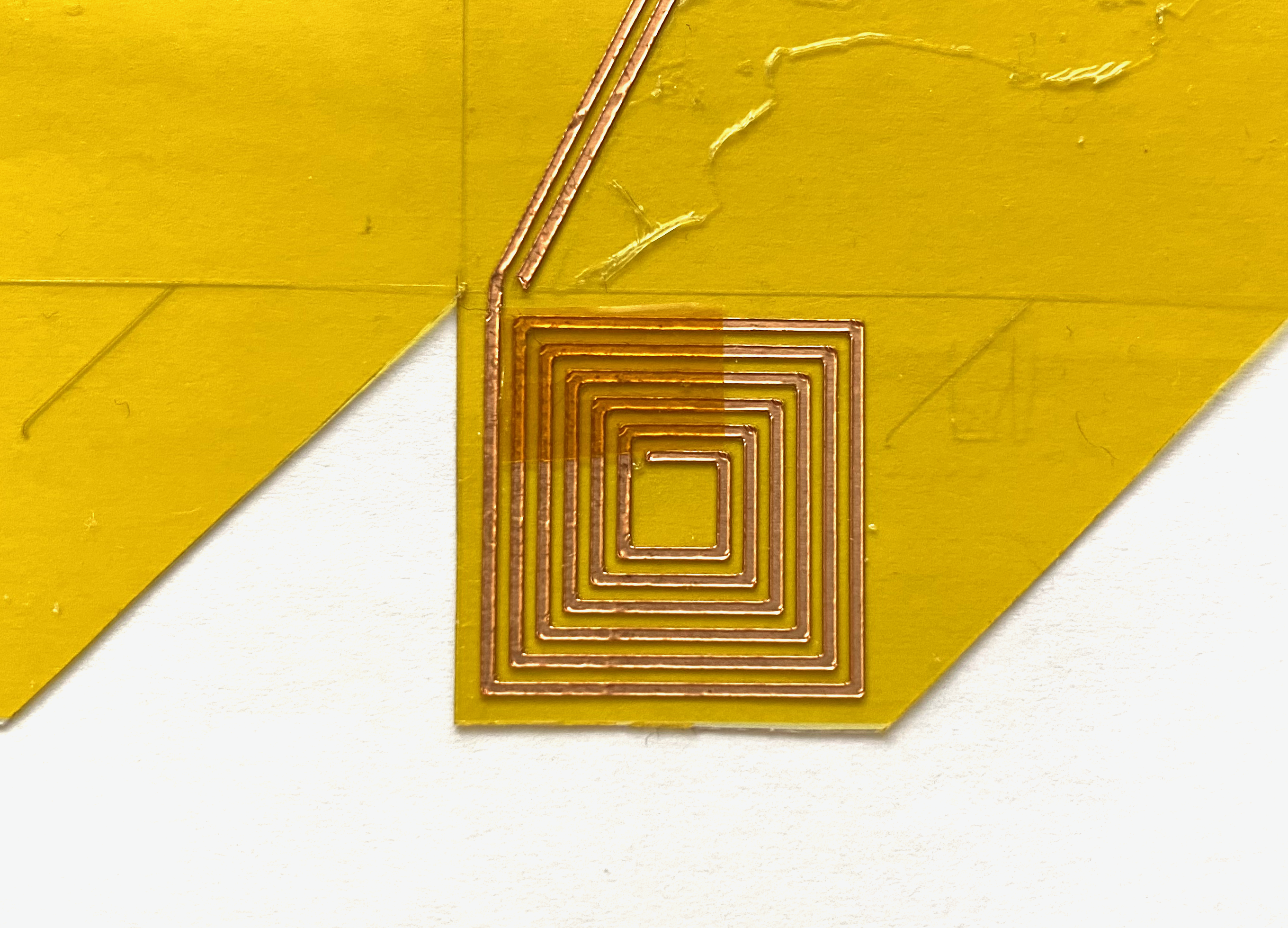

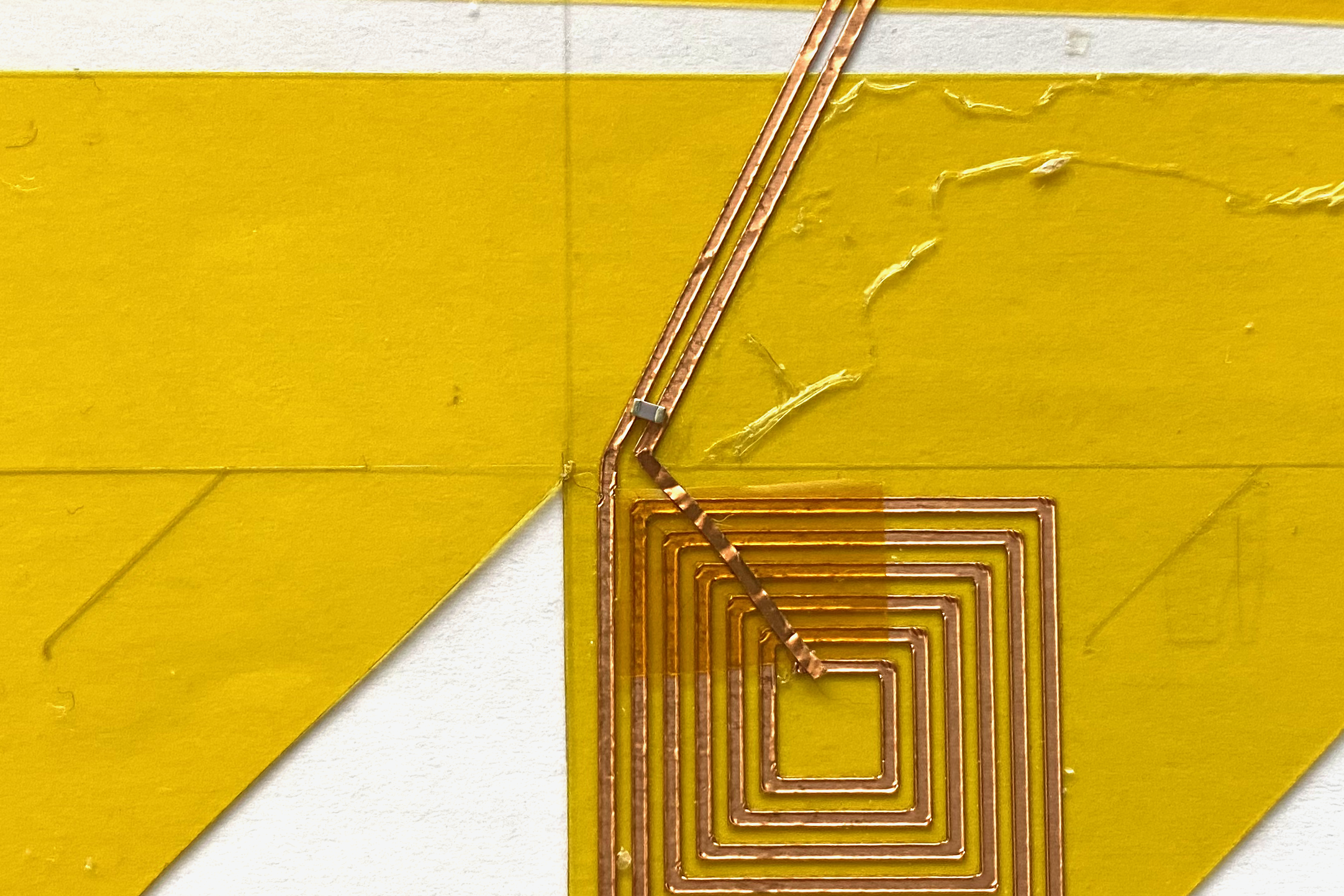

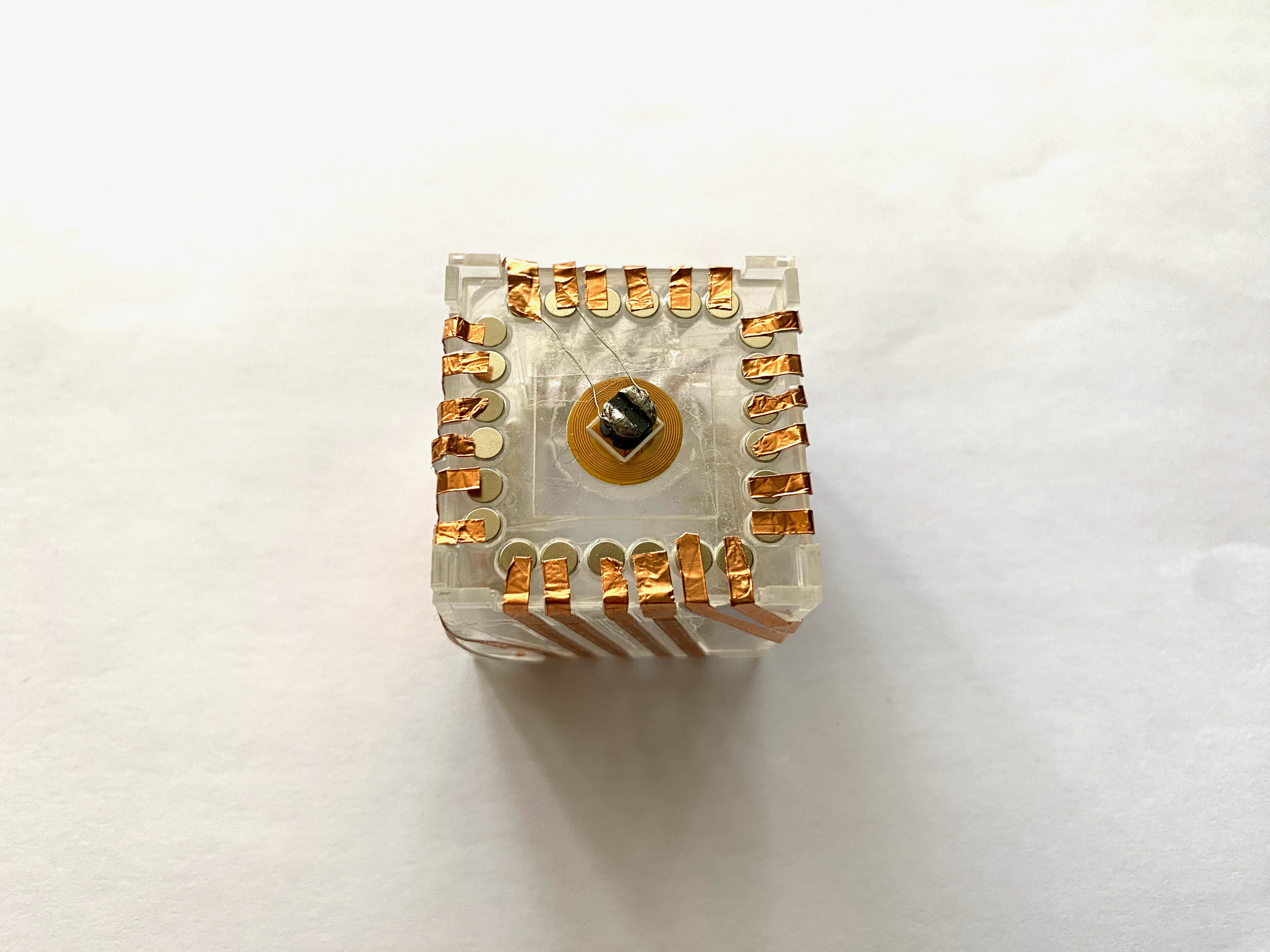

Brick

Tools

- Laser cutter

- Vinyl cutter

Materials

- Acrylic sheet (thickness: 1mm)

- Copper foil

- N35 neodymium magnets (3 mm (ϕ) × 1 mm (T))

- Convex N35 neodymium magnets (bottom side: 3 mm (ϕ) × 1 mm (T); top side had dimensions of 2 mm (ϕ) × 2 mm (T))

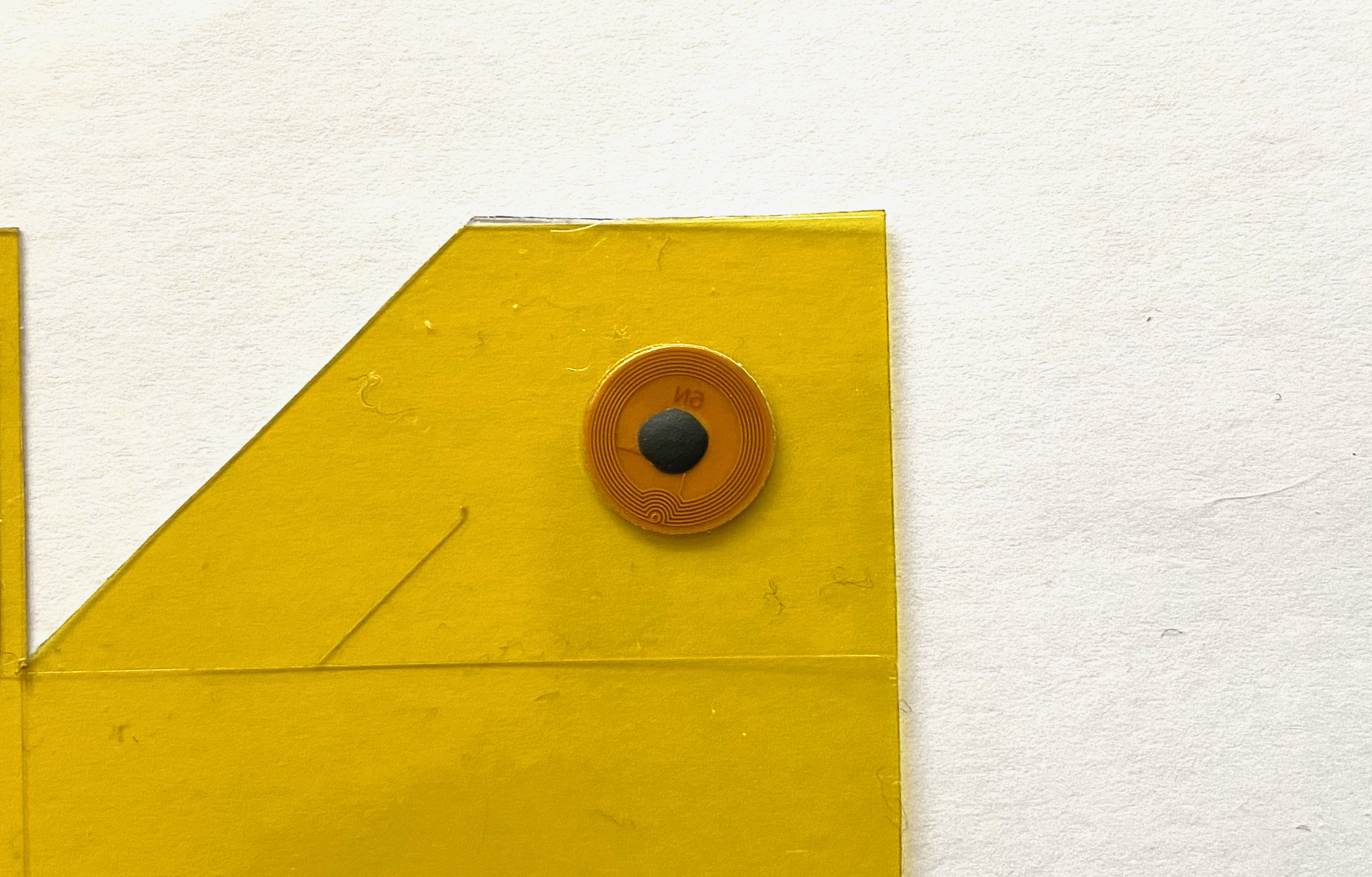

- NTAG213 NFC tag (diameter: 10mm)

- 1.4 uH Bourn SDR0403-1R4ML unshielded inductor (4.5 mm (ϕ) × 3.2 mm (T))

- Tape

Fabrication

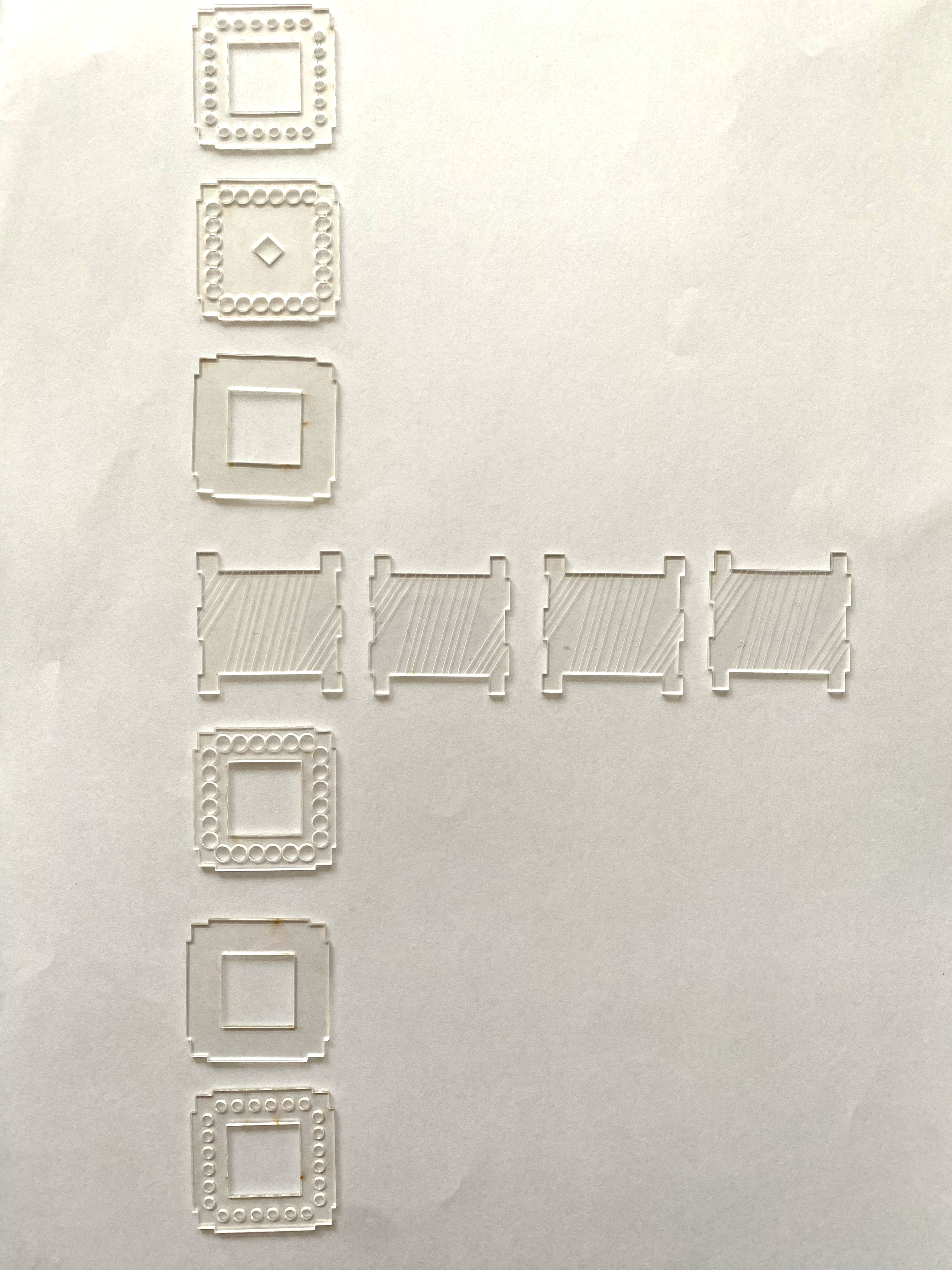

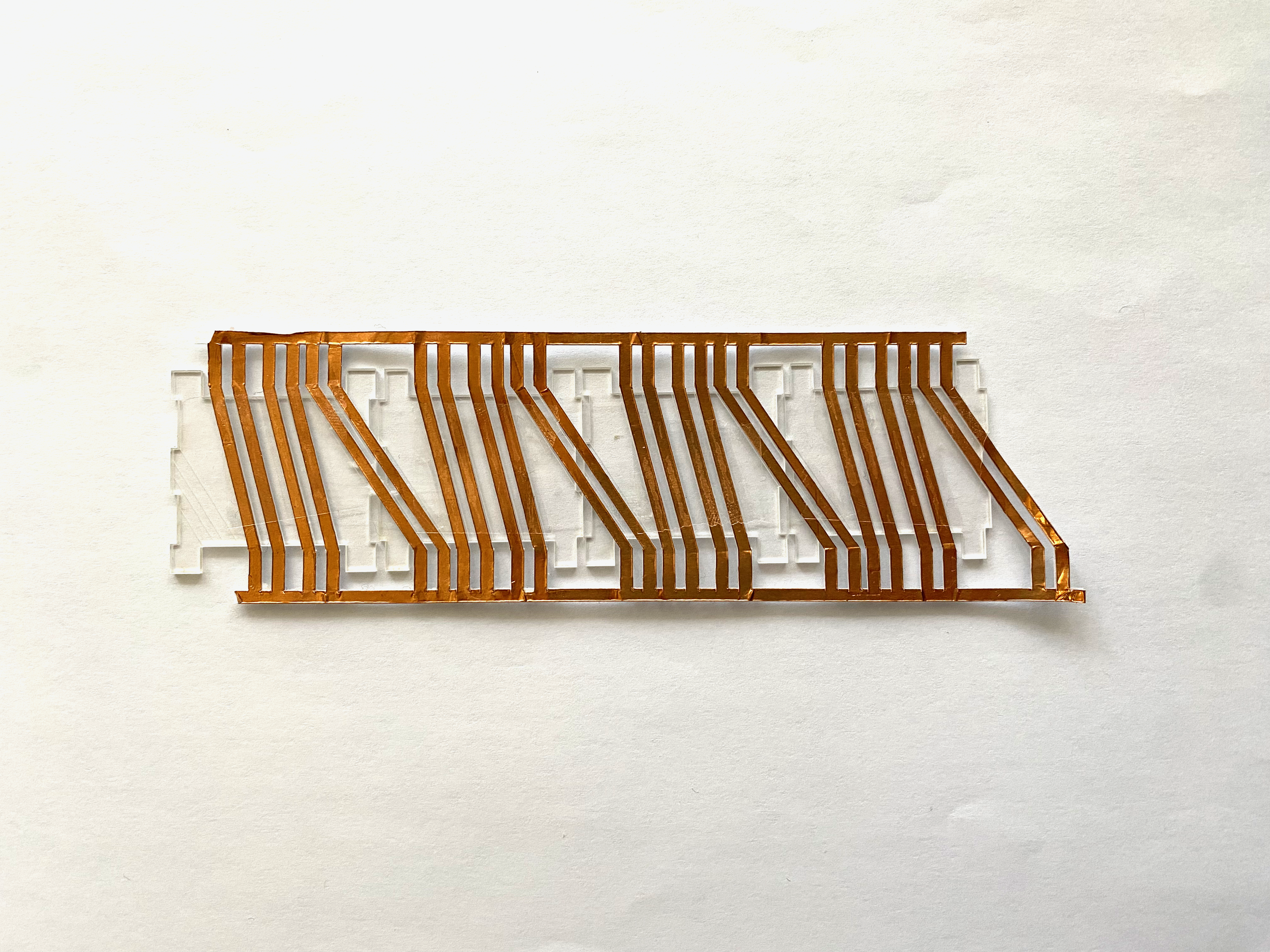

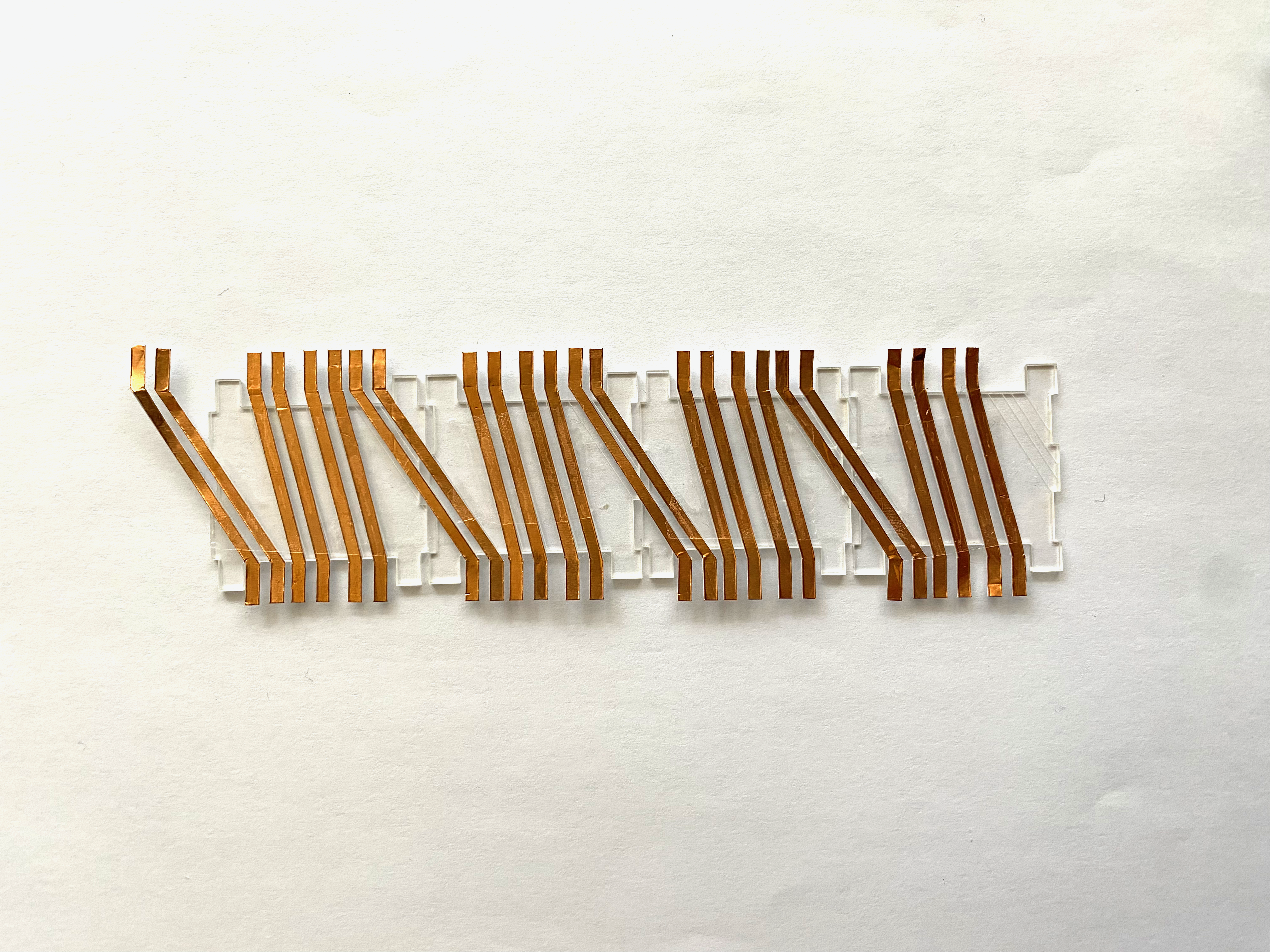

- Laser-cut the acrylic sheet for the structure (file)

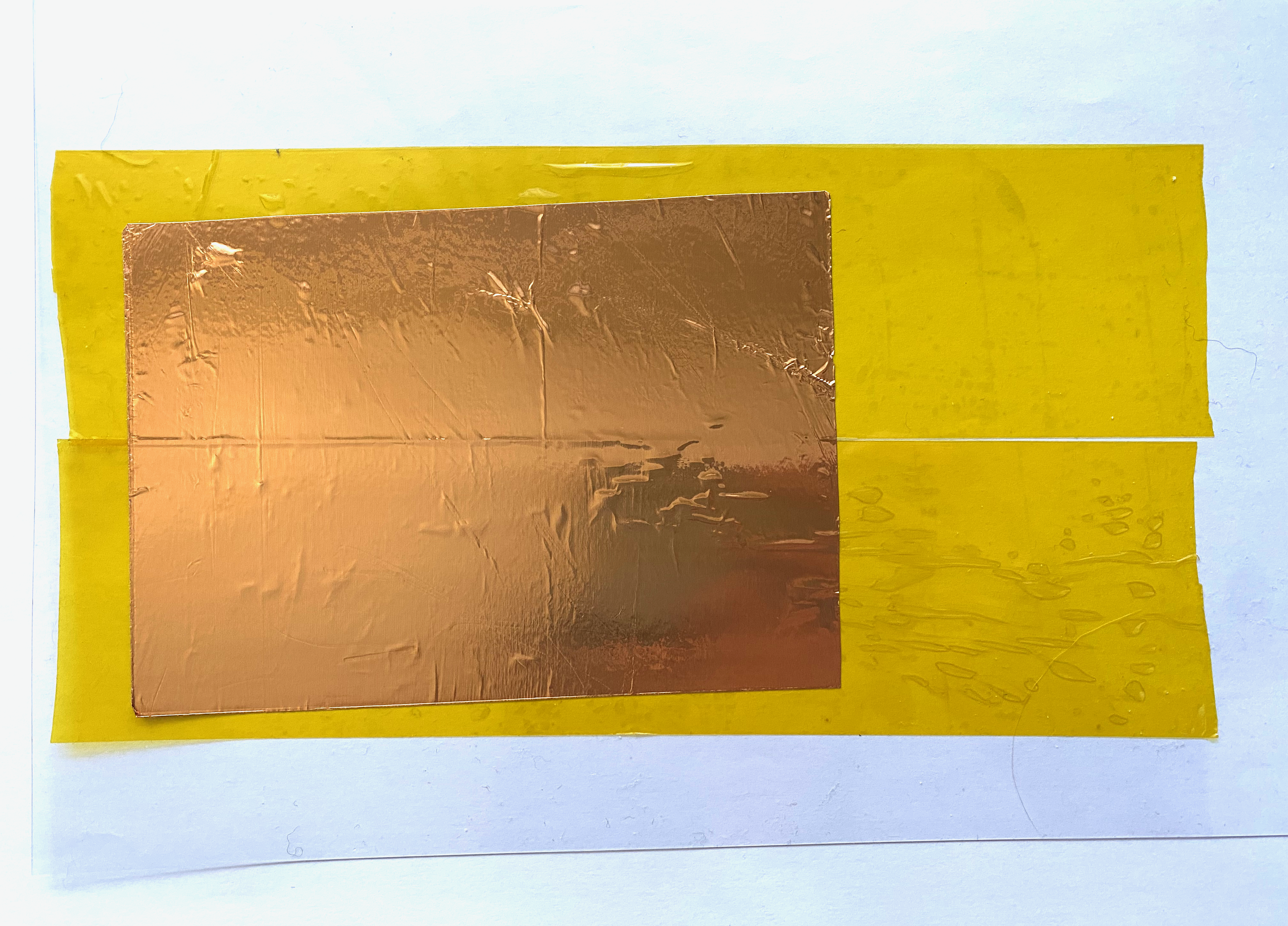

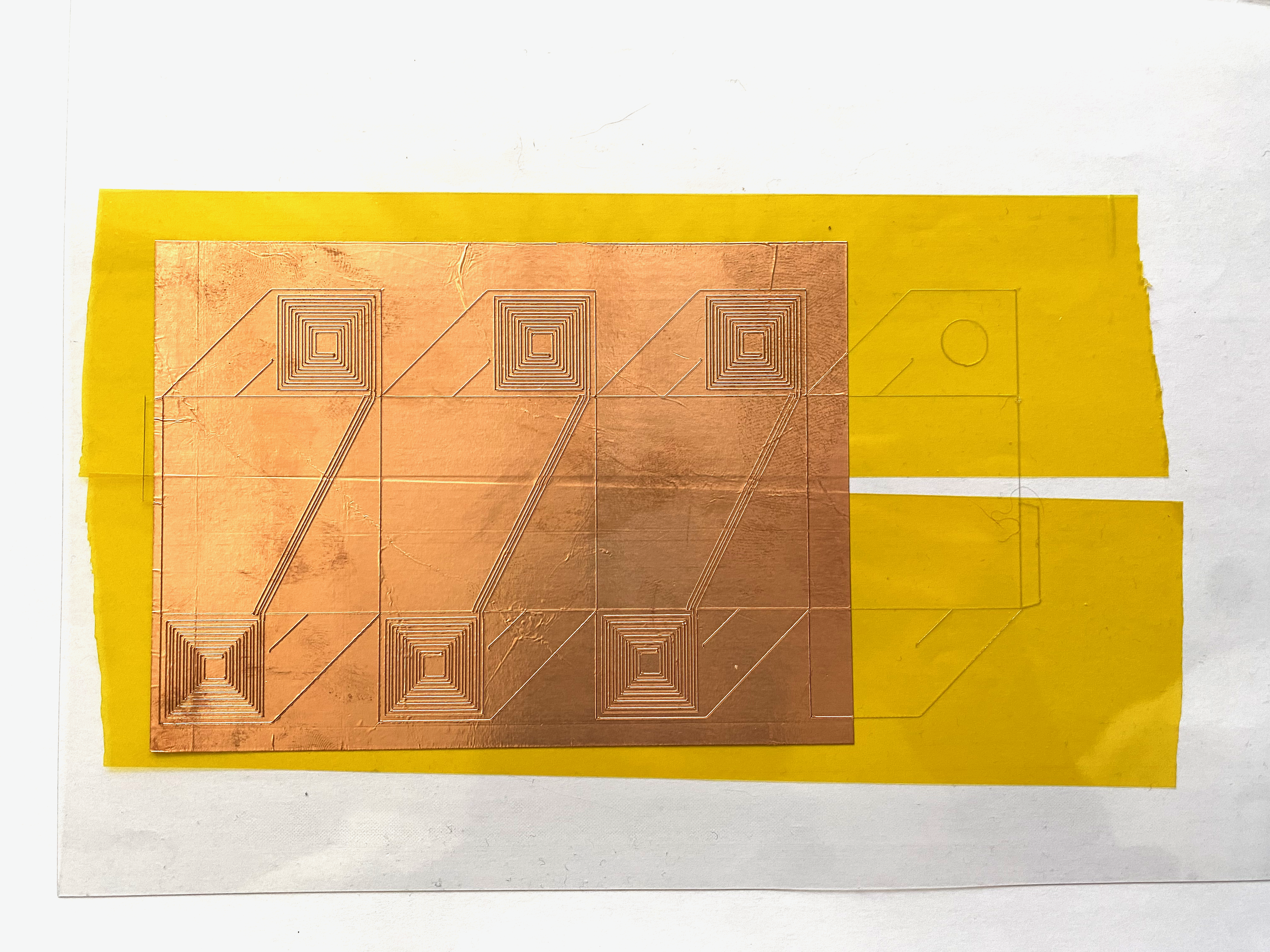

- Vinyl-cut the copper foil for the transmission lines (file)

- Attach the transmission line to the acrylic structure

- Cut the connecting part of the transmission lines

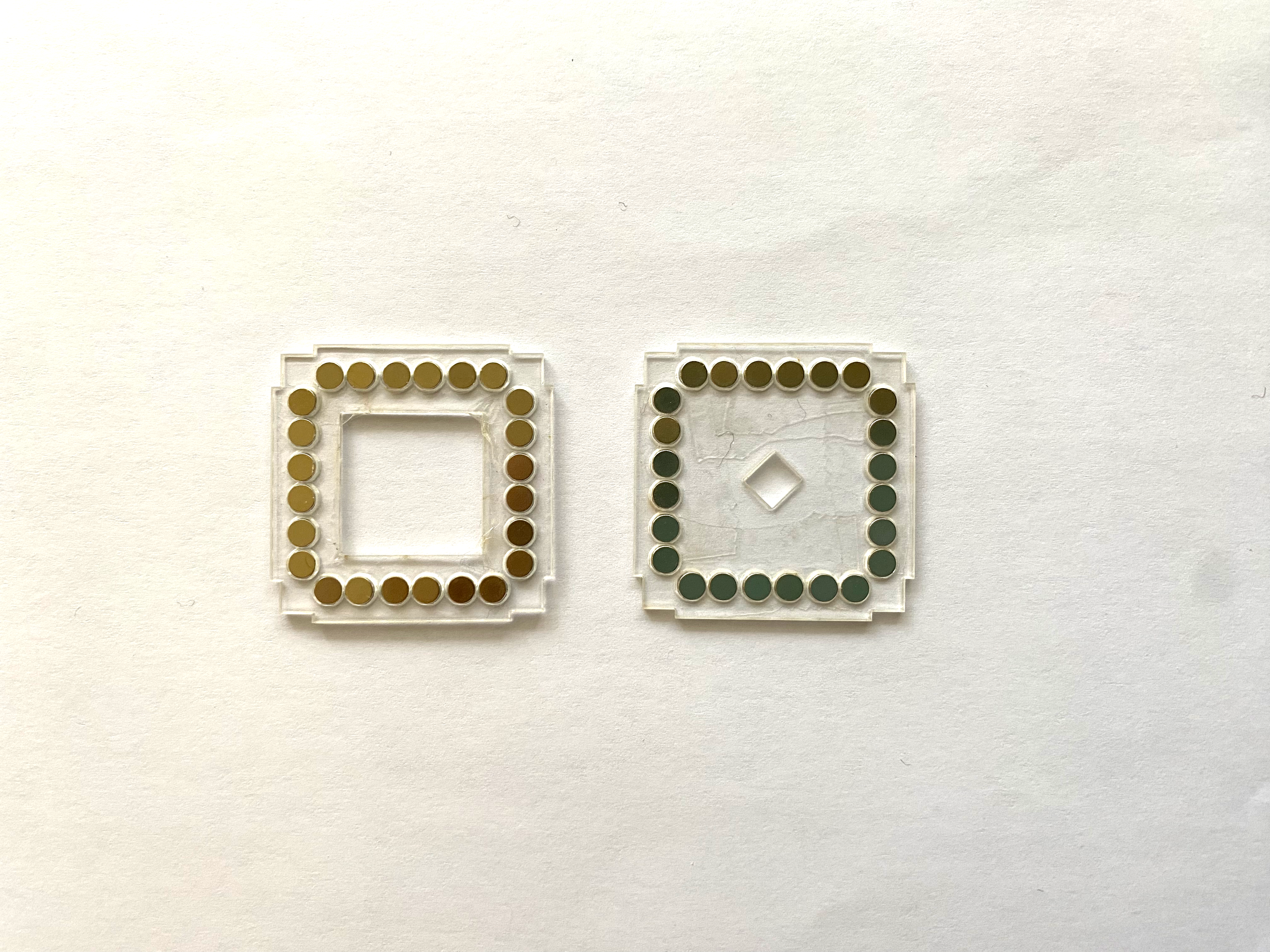

- Put the magnets in the acrylic structure

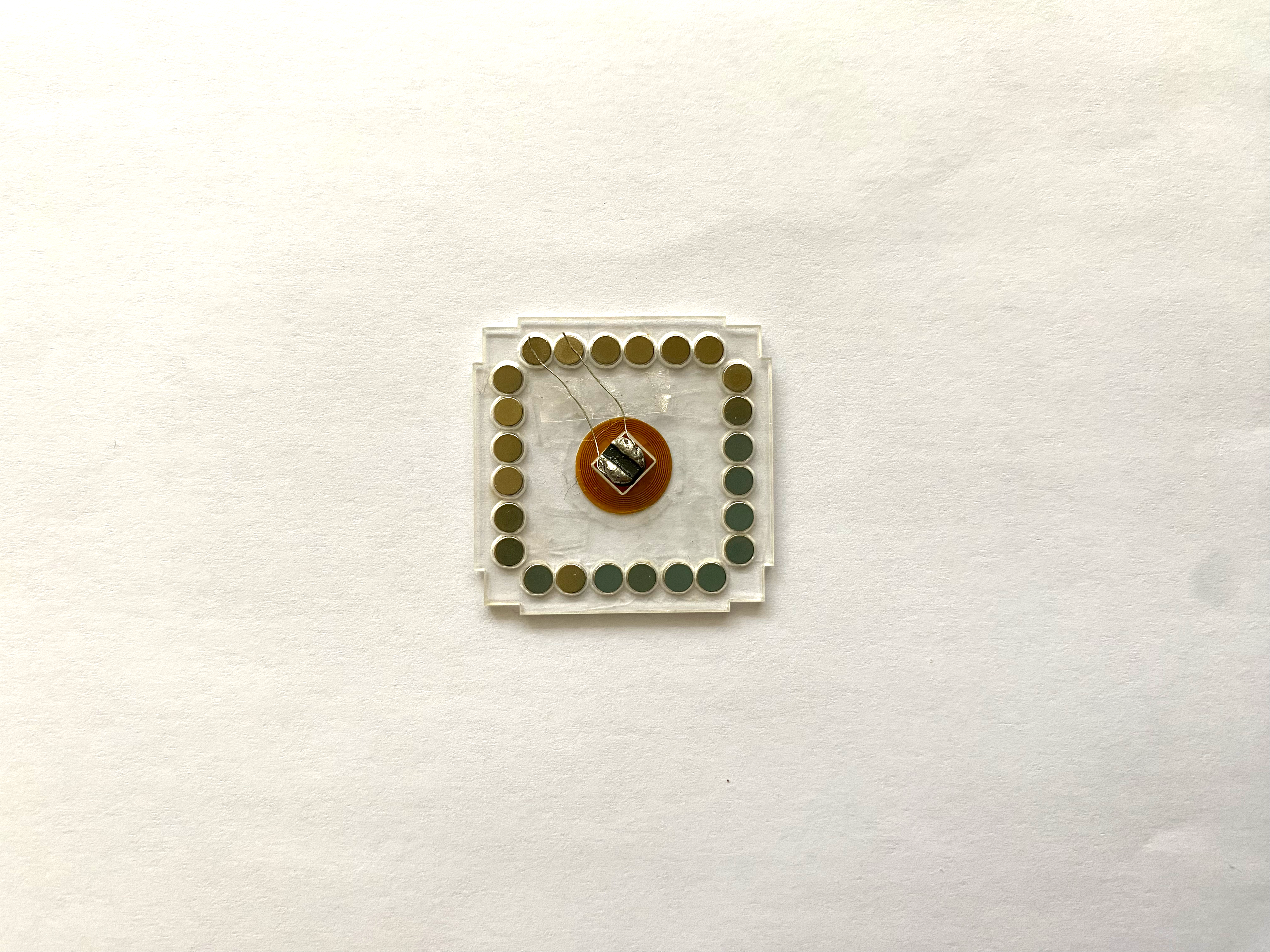

- Paste the NFC tag and connect the inductor to the connectors

- Assemble the brick and paste the transmission lines on the magnets

- Put the convex magnets on the transmission lines and keep the convex magnets in the place with acrylic structure

- Hold the structure with tapes

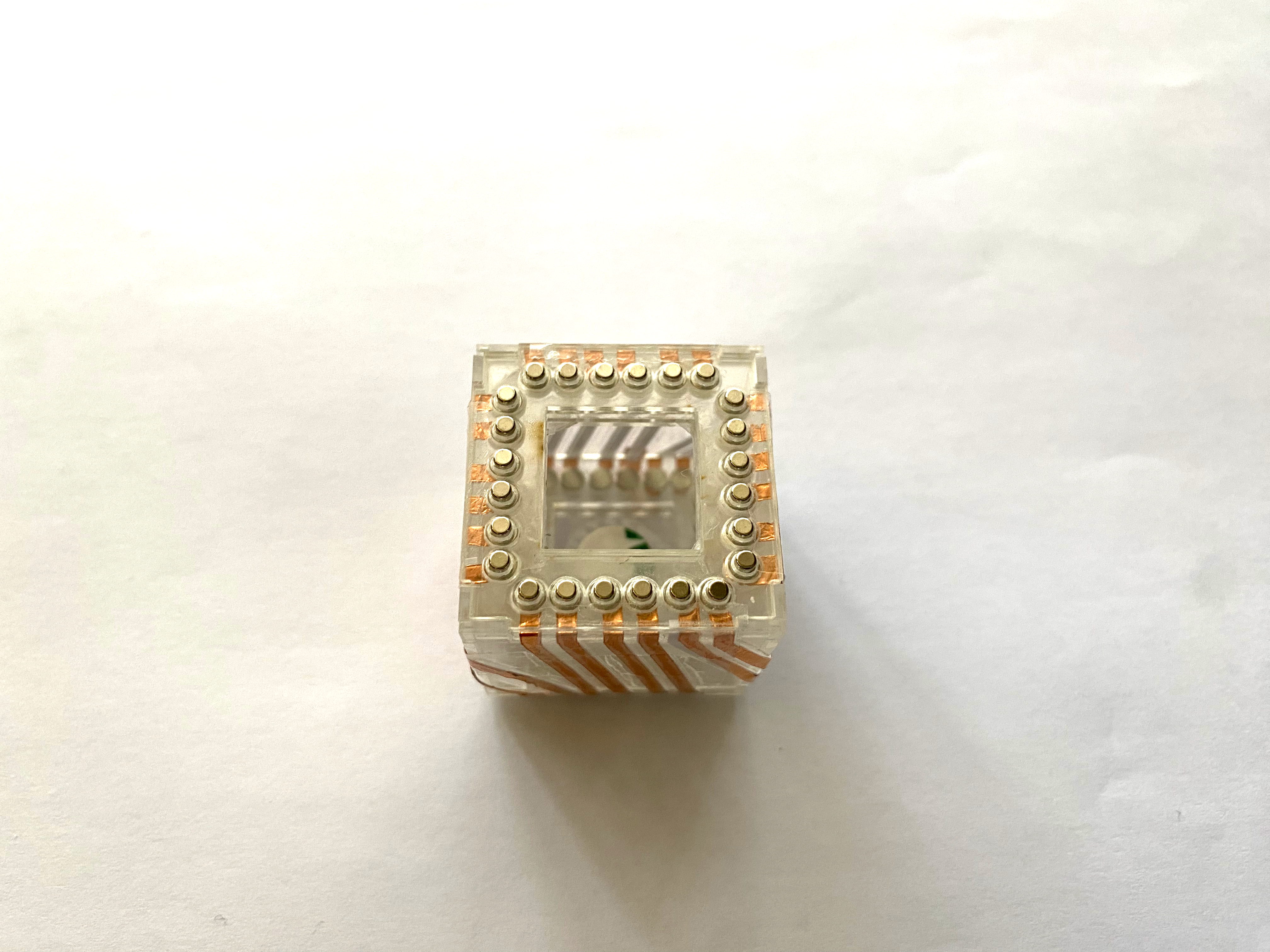

Box

Tools

- Vinyl cutter

- Soldering iron

- Scissors

Materials

- Polyethylene sheet (thickness: 0.25mm)

- Copper foil

- Polyimide film tape

- 300pF SMT capacitor

- NTAG213 NFC tag (diameter: 10mm)

- 1.4 uH Bourn SDR0403-1R4ML unshielded inductor (4.5 mm (ϕ) × 3.2 mm (T))

- Tape

Fabrication

- Attach the polyimide film tape to the polyethylene sheet

- Attach the copper foil to the polyimide film tape

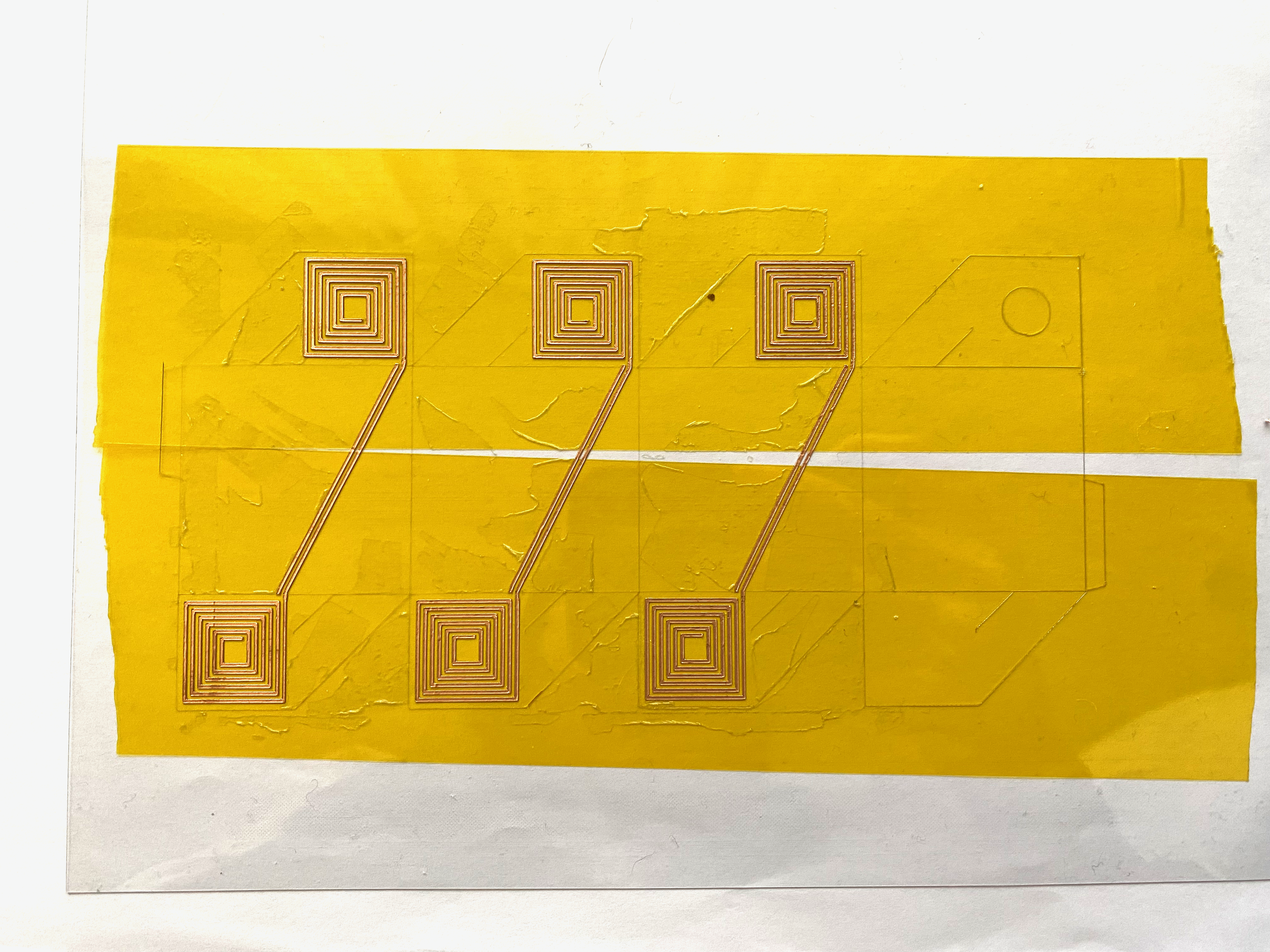

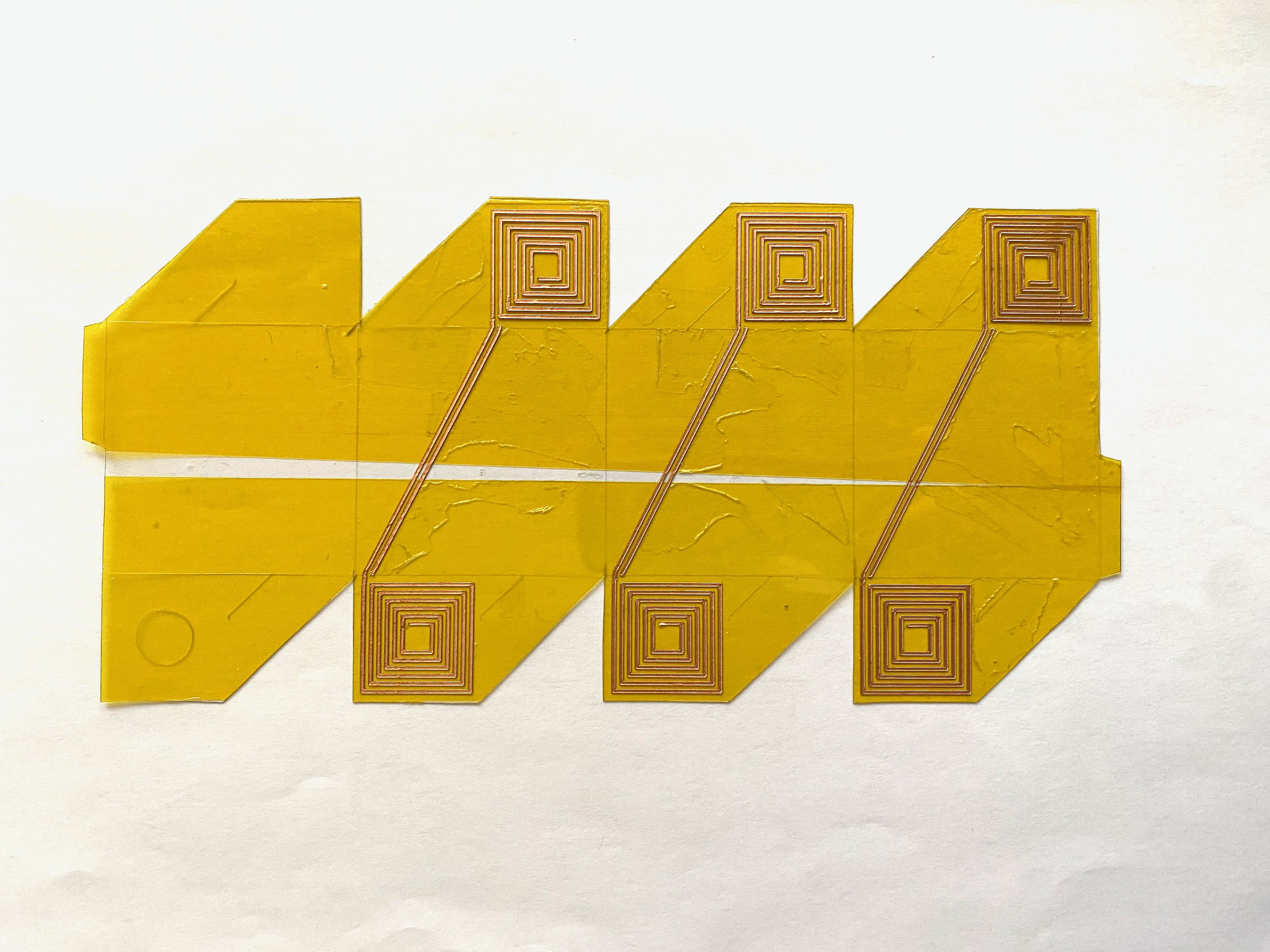

- Vinyl-cut the structure of the box(file)

- Remove the unwanted copper foil

- Cut the box down

- Paste polyimide film tape for insulation

- Complete the coil

- Solder the capacitors

- Paste the NFC tag

- Assemble the box